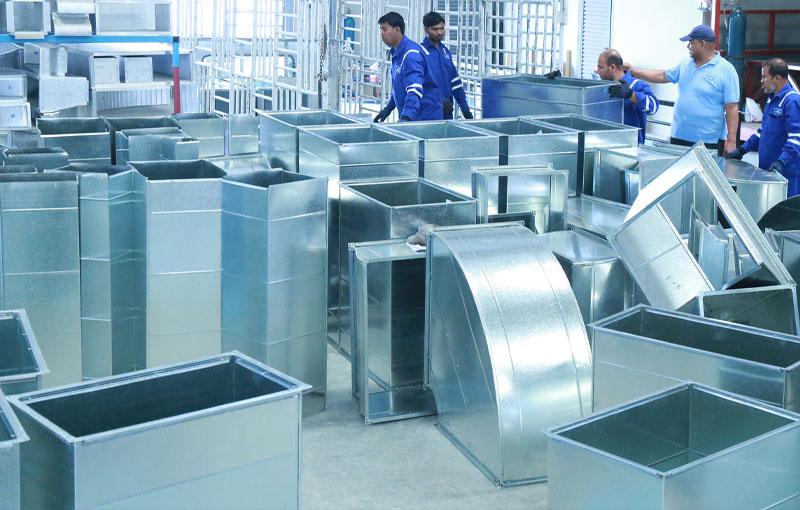

Ductwork fabrication is a critical component of HVAC system manufacturing, involving processes such as cutting, bending, rolling, punching, and assembling metal or composite materials. While these processes are essential for producing high-quality duct systems, they also present several safety risks for workers. From handling sharp metal sheets to operating heavy machinery, a ductwork fabrication workshop requires stringent safety practices to protect employees, maintain efficiency, and prevent accidents.

Implementing proper safety measures in ductwork fabrication workshops not only safeguards workers but also enhances productivity and ensures the quality of the manufactured components. Understanding potential hazards and establishing clear protocols are essential for any facility involved in duct manufacturing.

Table of Contents

TogglePersonal Protective Equipment (PPE)

One of the fundamental safety practices in ductwork fabrication is the use of appropriate personal protective equipment (PPE). Workers are frequently exposed to sharp edges, hot surfaces, heavy components, and airborne particles. PPE such as gloves, safety goggles, steel-toed boots, ear protection, and protective clothing significantly reduces the risk of injuries.

Gloves protect against cuts from metal sheets, while goggles shield eyes from flying debris during cutting, punching, or grinding operations. Ear protection is essential in high-noise environments created by hydraulic presses, shears, and rolling machines. Ensuring that all workers consistently use PPE is a critical step in creating a safe fabrication workshop.

Machine Safety and Operation Protocols

Machinery used in ductwork fabrication, including shears, press brakes, rollers, and CNC machines, presents significant risks if not operated properly. Implementing machine-specific safety protocols is essential. Workers should receive thorough training on the correct operation of each piece of equipment, including start-up, shutdown, emergency stops, and routine maintenance procedures.

Safety guards and emergency stop buttons should be installed on all machinery to prevent accidents. Additionally, only trained personnel should operate machines, and supervisors must ensure that standard operating procedures are consistently followed. Proper maintenance of equipment reduces the likelihood of mechanical failure, which can cause serious injuries or production downtime.

Safe Material Handling

Metal sheets, insulation panels, and other ductwork materials are often heavy and unwieldy. Improper handling can result in strains, sprains, or crushing injuries. To mitigate these risks, workshops should employ mechanical aids such as hoists, trolleys, and forklifts when moving large components.

Training workers in correct lifting techniques, including bending at the knees and avoiding twisting motions, is equally important. Clear pathways should be maintained to prevent tripping hazards, and materials should be stored safely to avoid accidental toppling or collisions.

Fire Prevention and Electrical Safety

Ductwork fabrication workshops often involve electrical equipment, welding, or hot cutting tools, all of which can pose fire hazards. Fire safety practices should include the installation of fire extinguishers, clear access to emergency exits, and the establishment of a fire response plan.

Electrical safety is also critical. Wiring and outlets must comply with local regulations, and machines should be properly grounded. Workers should be trained to identify electrical hazards and avoid overloading circuits or using damaged equipment. Regular inspection and preventive maintenance of electrical systems reduce the risk of fires and electrical accidents.

Proper Ventilation and Dust Control

Cutting, grinding, and sanding metal sheets can produce airborne particles that pose respiratory hazards. Proper ventilation and dust extraction systems help maintain air quality in the workshop. Workers should also wear respiratory protection when necessary, especially during operations that generate significant metal dust or fumes.

Regular cleaning of the workspace prevents accumulation of dust and debris, reducing fire risk and ensuring a safer, more organized environment. Clear labeling of hazardous areas and materials contributes to overall workshop safety.

Emergency Preparedness and Training

Even with the best preventive measures, accidents can occur. Ductwork fabrication workshops should have clear emergency protocols, including evacuation plans, first aid stations, and access to medical assistance. Conducting regular safety drills ensures that employees know how to respond to emergencies efficiently.

Ongoing training programs on safety awareness, proper equipment use, and hazard recognition empower workers to actively participate in maintaining a safe environment. Encouraging a safety-first culture reduces the likelihood of accidents and fosters accountability among all team members.

Conclusion

Safety in ductwork fabrication workshops is critical for protecting workers, maintaining productivity, and ensuring high-quality duct production. Key practices include the use of personal protective equipment, machine safety protocols, proper material handling, fire and electrical precautions, ventilation, and emergency preparedness.

By consistently implementing these safety measures and promoting a culture of awareness, workshops can reduce accidents, enhance efficiency, and support a reliable manufacturing process. Prioritizing safety not only protects employees but also contributes to the long-term success of any ductwork fabrication operation.