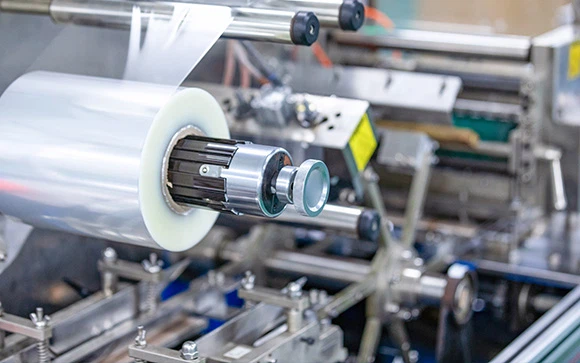

Water soluble film packaging machines have transformed modern manufacturing by offering precise, eco-friendly, and versatile packaging solutions for liquids, powders, and gels. These machines use polyvinyl alcohol (PVA) films that dissolve completely in water, enabling single-use packaging that is both convenient and environmentally responsible. As industries move toward smart manufacturing and Industry 4.0 practices, integrating water soluble film packaging machines into smart factories has become increasingly important for improving efficiency, reducing waste, and maintaining high-quality production standards.

Smart factories rely on interconnected systems, real-time data monitoring, and automation to optimize production processes. Water soluble film packaging machines, when integrated into these systems, can communicate with other machinery, share operational data, and respond dynamically to production demands. This integration enhances productivity, reduces human error, and allows manufacturers to make data-driven decisions for continuous improvement.

Table of Contents

ToggleAutomation and Data Connectivity

One of the key aspects of smart factory integration is automation. Modern water soluble film packaging machines incorporate programmable logic controllers (PLCs), touch-screen human-machine interfaces (HMIs), and automated sensors to control every aspect of pouch formation, filling, and sealing. These machines can adjust dosing, sealing pressure, and film tension in real time, ensuring consistent quality and minimal waste.

Data connectivity further enhances operational efficiency. Machines can transmit production data, error logs, and performance metrics to centralized factory management systems. This allows plant managers to monitor multiple machines simultaneously, detect issues early, and optimize production schedules. In the middle of advanced manufacturing processes, the Water Soluble Film Packaging Machine integrates seamlessly into smart factory ecosystems, enabling automated quality checks, real-time monitoring, and efficient resource management while ensuring eco-friendly packaging outcomes.

Real-Time Monitoring and Predictive Maintenance

Smart factory integration allows for real-time monitoring of machine performance. Sensors on water soluble film packaging machines track key parameters such as motor load, seal temperature, film alignment, and fill accuracy. Any deviation from set parameters triggers alerts, enabling operators to address issues before they result in defective packages or machine downtime.

Predictive maintenance is another advantage. By analyzing historical performance data and sensor readings, manufacturers can anticipate wear and tear on components such as pumps, nozzles, rollers, and sealing heads. Scheduled maintenance can then be performed proactively, reducing unplanned downtime, extending machine life, and lowering operational costs.

Efficiency and Waste Reduction

Integrating water soluble film packaging machines into smart factories improves overall production efficiency. Automated dosing ensures accurate product quantities, minimizing overfilling or underfilling. Film tension and alignment controls prevent material waste caused by tearing or misaligned pouches. Additionally, smart factory systems can optimize production speed based on demand, reducing idle time and energy consumption.

This integration also contributes to sustainability goals. Precise control over product and film usage reduces material waste, while energy-efficient motors and optimized heating systems minimize power consumption. Manufacturers can achieve higher throughput with less environmental impact, aligning production practices with modern sustainability initiatives.

Quality Control and Compliance

Smart factories enable advanced quality control systems to work alongside water soluble film packaging machines. Vision systems, weight sensors, and seal detection technologies monitor each pouch for defects in real time. Data from these systems can be logged for traceability, ensuring compliance with industry standards in pharmaceuticals, food, and chemicals.

Integration with factory-wide monitoring systems allows manufacturers to maintain consistent quality across multiple production lines. Any deviations from standards can trigger immediate corrective action, preventing defective products from reaching consumers and ensuring regulatory compliance.

Flexibility and Multi-Product Production

Smart factory integration also enhances flexibility. Water soluble film packaging machines can switch between liquids, powders, and gels with minimal manual adjustments. By storing multiple product recipes and machine parameters digitally, production lines can quickly adapt to new products or batch sizes, reducing changeover time and minimizing waste.

This capability is particularly valuable for manufacturers producing diverse product lines or handling seasonal demand variations. Combined with real-time monitoring and automated quality checks, multi-product production becomes more efficient and reliable.

Conclusion

Water soluble film packaging machines are a key component in modern, smart factory operations. By integrating these machines into automated, data-driven production systems, manufacturers can achieve higher efficiency, consistent quality, reduced waste, and improved sustainability. Real-time monitoring, predictive maintenance, and automated quality control enhance operational reliability, while flexible production capabilities support diverse product lines. Leveraging the capabilities of the Water Soluble Film Packaging Machine within a smart factory ecosystem allows businesses to meet modern manufacturing demands while maintaining eco-friendly packaging practices, operational excellence, and regulatory compliance.